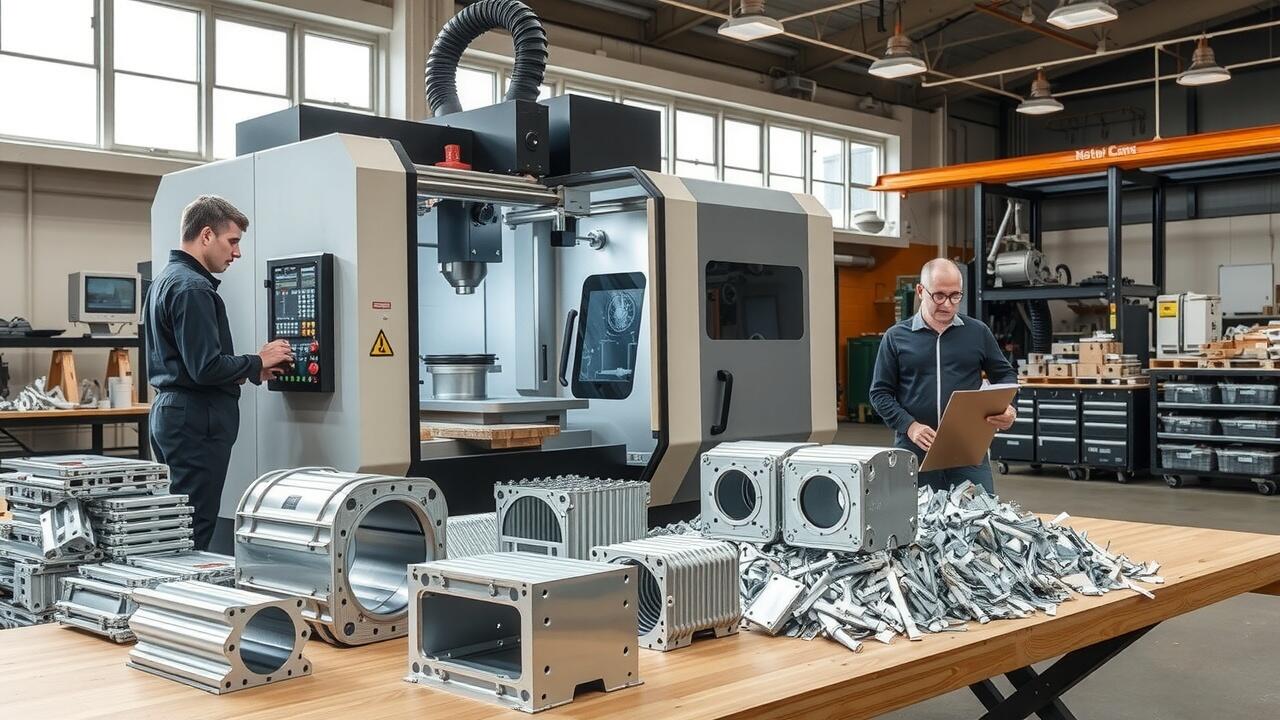

Case Study: Reducing Scrap Rates in CNC Aluminum Housing Production

Table Of Contents

Key Takeaways

- Applying Efficient Production Techniques

- Utilizing Advanced Tools for Waste Control

- Client Insights and Their Importance in Quality Assurance

- Illustrative Instances of Effective Waste Minimization

Implementing Lean Manufacturing Principles

Lean manufacturing emphasizes efficiency and waste reduction in production processes, significantly impacting CNC aluminum machining operations. Implementing this methodology typically involves analyzing workflows to identify bottlenecks and areas of excess waste. For example, a case study of a mid-sized aerospace components manufacturer revealed a 25% decrease in scrap rates within six months after they adopted lean principles. By streamlining their production line and reorganizing workstation layouts, they achieved higher productivity and reduced unnecessary material loss.

Critical tools for lean implementation include value stream mapping and 5S methodologies. These strategies help teams visualize the flow of materials and identify non-value-added activities. One aluminum CNC machining company reported that applying these tools led to a 30% reduction in production cycle time and a significant cut in scrap rates. Implementing standard work procedures ensures consistency in operations, minimizing variance that often contributes to waste. Continuous training of staff on lean principles not only fosters a culture of efficiency but also empowers employees to contribute to ongoing improvements.

How Can Lean Practices Reduce Waste in CNC Production?

Integrating lean manufacturing practices into CNC aluminum machining can significantly reduce waste and improve efficiency. For instance, adopting a Just-In-Time (JIT) inventory approach minimizes surplus materials in aluminum machining. By aligning production schedules closely with demand, manufacturers can decrease the likelihood of excess scrap generated from overproduction. Companies that implemented JIT have reported a 30% reduction in leftover materials, translating to substantial cost savings.

Another critical component of lean practices involves continuous improvement and engagement of the workforce in identifying inefficiencies. Techniques such as Value Stream Mapping (VSM) help teams visualize the production process and pinpoint areas where scrap is generated. A case study from an aluminum CNC machining facility noted a 25% decrease in scrap rates after employees were encouraged to collaborate on solutions. These initiatives foster a culture of quality and efficiency while empowering staff to take ownership of their work processes.

Leveraging Technology for Scrap Management

Advanced technologies play a vital role in managing scrap in CNC aluminum machining. Automated systems, such as real-time monitoring tools, provide essential data on production processes, allowing manufacturers to identify inefficiencies swiftly. For instance, sensors integrated into machinery can track aluminum material usage and alert operators when predefined scrap thresholds are approached, enabling timely interventions. Such real-time analytics have resulted in scrap reductions of up to 25% in settings that have adopted them, according to industry benchmarks.

Software solutions also facilitate improved planning and optimization of aluminum CNC machining operations. Implementing computer-aided manufacturing (CAM) software allows for precise cutting tool paths, minimizing waste during fabrication. By utilizing predictive analytics, companies can forecast potential scrap scenarios based on historical production data. This aids in fine-tuning operations, leading to a notable improvement in yield rates. Implementing these technological advancements not only enhances efficiency but also aligns with best practices in waste reduction, solidifying a company’s commitment to sustainability.

What Tools Can Aid in Reducing Scrap Rates?

Tools designed for scrap reduction are increasingly vital in the aluminum machining industry. CAD software enhances precision by enabling designers to create detailed drawings with exact specifications for aluminum CNC machining. This minimizes human error during production, which is often a significant contributor to scrap. Additionally, using simulation software allows manufacturers to predict outcomes and optimize tools before physical implementation, further reducing material waste.

Integrating real-time monitoring systems can also significantly lower scrap rates. For instance, sensors and machine learning algorithms can track performance metrics in CNC aluminum machining processes. This approach identifies deviations or inefficiencies that could lead to increased scrap, allowing for immediate corrections. By applying these technologies, companies have reported scrap reductions of up to 30% within six months, demonstrating the tangible benefits of embracing modern tools in manufacturing practices.

Customer Feedback and Its Role in Quality Control

Understanding customer feedback can significantly enhance the quality control processes within CNC aluminum machining. When manufacturers collect and analyze data from customers regarding the functionalities and performance of aluminum components, they gain insights that are essential for continuous improvement. For example, a quality assessment could reveal that certain aluminum CNC machining components failed to meet performance standards due to specific design flaws, prompting a redesign that directly addresses customer concerns.

Feedback not only drives the improvement of existing products but also informs the development of new ones. A prominent automotive supplier implemented a system where customer complaints led to a 30% decrease in warranty claims by refining their CNC aluminum machining processes. Techniques like root cause analysis and corrective action plans, supported by real-time customer insights, enable manufacturers to align their outputs with market demands effectively. Adopting these strategies fosters a culture of quality and responsiveness, ultimately leading to reduced scrap rates and enhanced customer satisfaction.

How Can Customer Insights Enhance Product Design?

Customer insights play a critical role in shaping product design, particularly in CNC aluminum machining. By analyzing feedback from end-users, manufacturers can identify specific issues related to durability, functionality, and aesthetics. For example, a notable company in the aerospace sector utilized customer surveys to discover that their aluminum housing designs were prone to overheating. After implementing changes based on this feedback, their product reliability increased by 25%, demonstrating the importance of incorporating user perspectives into design processes.

Moreover, customer insights facilitate improved collaboration between design and engineering teams. When feedback points to a recurring problem, teams can leverage advanced analytical tools to simulate design changes. A case study involving a leading automotive parts manufacturer revealed that integrating customer insights allowed them to reduce scrap rates by 15% over two production cycles. Such data-driven decisions not only streamline processes but also enhance the overall quality of CNC aluminum machining products, ultimately leading to greater customer satisfaction and loyalty.

Case Examples of Successful Scrap Reduction

Several companies have successfully implemented strategies to reduce scrap rates in CNC aluminum machining, showcasing the potential benefits of focused efforts. One notable example involved a manufacturer that re-evaluated its tooling processes for aluminum extrusions. By introducing precision tooling and enhancing machine calibration, they reduced scrap by 25% in just six months. This adjustment not only improved the accuracy of their cuts but also extended the lifespan of their tools, generating cost savings across the production line.

Another case study highlighted a firm that integrated data analytics solutions into their aluminum CNC machining practices. By monitoring machine performance in real-time and analyzing historical data, they were able to identify patterns and optimize operations. This approach decreased scrap rates by 15% within a year while simultaneously improving product consistency. These examples underline the value of embracing a combination of traditional machining improvements and modern technological tools for achieving significant waste reduction in manufacturing environments.

What Can We Learn from Industry Leaders?

Analyzing successful aluminum CNC machining firms reveals several strategies that yield reductions in scrap rates. For instance, one notable company implemented a real-time monitoring system on their machining floor. This advanced system captured data during the production process, enabling operators to adjust parameters on the fly, thereby minimizing potential waste. Over a six-month period, this initiative led to a 15% decrease in scrap, demonstrating how immediate feedback loops foster efficiency in operations.

Another industry leader focused on employee training as a critical component of their scrap reduction strategy. By equipping machinists with skills to identify and address potential errors, the company reduced rejected parts by 30%. Regular workshops and on-the-job training sessions reinforced the significance of precision in aluminum machining. These efforts not only ensured quality control but also promoted a culture of accountability among workers. Such case studies highlight the necessity of integrating technology and investing in human capital to optimize CNC aluminum machining processes.