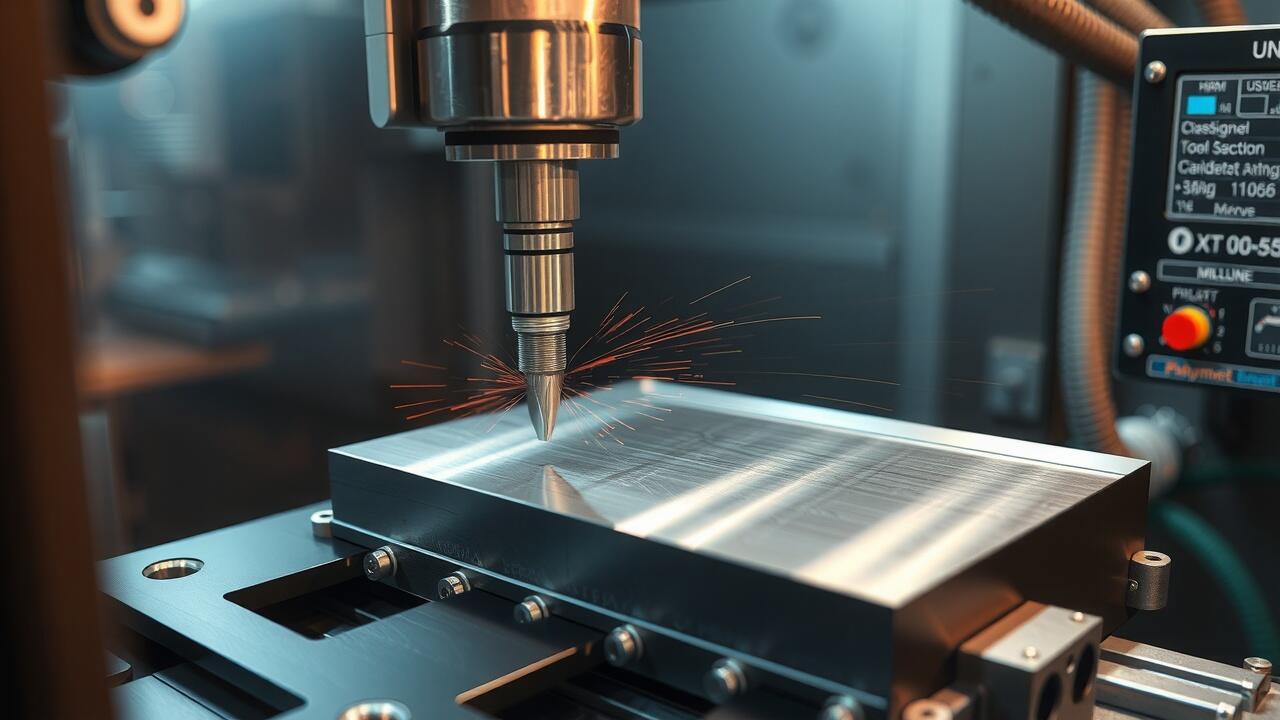

Overcoming Tool Deflection Challenges in High-Speed CNC Aluminum Milling

Table Of Contents

Key Takeaways

- Modifying equipment settings to address tool bending

- The significance of workpiece arrangement for tool steadiness

- Utilizing immediate oversight for tool efficiency

- Evaluating cutting circumstances to enhance tool durability

Adjusting Machine Parameters to Combat Tool Deflection

Adjusting machine parameters significantly impacts the overall performance during aluminum CNC machining. Modifying the spindle speed and feed rate can help reduce tool deflection. For instance, higher spindle speeds can decrease the cutting forces, allowing the tool to maintain a more stable position while machining complex geometries. A study shows that optimizing the feed rates by 15% reduced deflection in one high-speed aluminum milling case, leading to increased accuracy in the finished parts.

In addition to spindle speed and feed rate, altering depth of cut parameters also plays a crucial role in maintaining tool stability. A shallower cut reduces the engagement of the tool with the workpiece, thereby lowering axial forces. Implementing these adjustments while closely monitoring thermal conditions can enhance tool integrity. Incorporating dynamic adjustments during the machining process is a best practice embraced in precision aluminum machining projects.

What Parameters Can You Modify to Lower Deflection Risks?

To combat tool deflection during aluminum CNC machining, adjusting feed rate and spindle speed becomes essential. Typically, reducing the feed rate minimizes the amount of material removed per pass, allowing the tool time to adapt to the cutting forces without deformation. For example, operating at a feed rate of 0.005 inches per revolution instead of 0.010 inches can significantly lower the risk of deflection in delicate aluminum parts. Additionally, fine-tuning spindle speed can influence thermal conditions and tool engagement, optimizing the cutting environment and potentially increasing tool life.

Modifying tool geometries also plays a critical role in decreasing deflection risks. Choosing tools with a higher helix angle or specific coatings can enhance chip evacuation and reduce friction, ultimately minimizing deflection. For instance, employing tools specifically designed for aluminum machining, such as solid carbide end mills with polished flutes, can lead to more efficient cutting while maintaining stability under high-speed conditions. Implementing a combination of these strategies ensures that CNC aluminum machining processes remain effective and reliable, ultimately enhancing productivity and reducing production errors.

The Role of Workpiece Setup in Tool Stability

Workpiece setup significantly influences tool stability during aluminum CNC machining processes. An improperly fixtured workpiece can lead to undesirable vibrations and increased tool deflection. For instance, using a fixture that does not adequately support the entire workpiece can result in flexing, particularly in thin-walled aluminum components. This can compromise the accuracy of cuts and lead to increased wear on cutting tools. Optimizing support through the use of appropriate workholding equipment, like specialized clamps or fixtures tailored for aluminum machining, adds stability and precision.

The type of material contact and the way a workpiece is secured determines its overall vibrational characteristics. Utilizing techniques such as distributed clamping can help evenly distribute cutting forces encountered during machining. A study examining various fixturing methodologies reported that improved fixture design reduced tool deflection by up to 20%, translating into better surface finishes and higher dimensional accuracy. Implementing these strategies not only assures consistent tool performance but also extends tool life, leading to reduced downtime and operational costs in high-speed CNC aluminum milling applications.

How Does Proper Fixturing Impact Tool Deflection?

Proper fixturing plays a crucial role in maintaining tool deflection control during CNC aluminum machining processes. A well-designed setup enhances the stability of the workpiece, reducing the likelihood of movement that can lead to inaccuracies. For instance, utilizing a rigid clamping system can prevent even minor shifts, which is vital when machining high-strength aluminum alloys. By ensuring that the workpiece is securely fastened, manufacturers can achieve tighter tolerances and improve surface finishes significantly.

Moreover, the positioning of fixtures can influence how forces are distributed across the tool and workpiece. When fixtures are positioned close to the cutting area, they can absorb vibrations more effectively, allowing for more stable machining conditions. In a case study, manufacturers who adopted modular fixturing systems observed a 20% reduction in tool wear and a notable increase in machining efficiency. Employing best practices in workpiece setup not only mitigates tool deflection risks but also enhances overall productivity in CNC aluminum machining processes.

Implementing Real-Time Monitoring for Tool Performance

Real-time monitoring systems enhance tool performance by enabling operators to track critical parameters throughout the CNC milling process. For instance, sophisticated sensors can measure vibrations and deviations in tool position with precision, allowing for immediate adjustments during aluminum CNC machining operations. A facility that integrated such monitoring tools reported a reduction in tool wear by 25%, significantly extending tool life and maintaining precision in machined components. This proactive approach not only increases productivity but also minimizes costly downtime associated with unexpected tool failures.

Using data analytics, operators can interpret sensor feedback to identify patterns leading to deflection. For example, by analyzing the correlation between cutting speeds and amplitude of vibrations, teams have been able to optimize their parameters effectively. Implementing thresholds for tool deflection alerts can trigger preventative action, providing a strategic advantage in high-speed aluminum machining contexts. These actionable insights guide decision-making, ensuring that operators continuously refine their processes for optimal performance.

Why Utilize Sensors to Track Tool Deflection During Milling?

Incorporating sensors during CNC aluminum machining enhances monitoring capabilities and enables real-time data collection. For instance, using piezoelectric sensors allows machinists to detect minute vibrations and displacements that are indicative of tool deflection. This immediate feedback can inform adjustments on the fly, preventing costly damage or reduced workpiece integrity. In a practical implementation, studies have shown that utilizing sensor technology can reduce scrap rates by up to 15%, demonstrating financial and operational advantages.

Moreover, integrating this technology aligns with industry standards for precision and productivity in aluminum CNC machining. Sensors can facilitate continuous data logging, which assists in identifying recurring issues or performance trends over time. By analyzing this data, manufacturers can implement preventive measures, optimizing their machining processes and significantly improving tool life. Leveraging such real-time insights leads to making informed decisions that enhance overall production efficiency and maintain high-quality output levels.

Analyzing Cutting Conditions to Improve Tool Integrity

Optimizing cutting speeds and feeds is essential for enhancing tool integrity during aluminum CNC machining. Studies have shown that operating within recommended parameters can significantly reduce tool wear and extend tool life. For instance, increasing the feed rate can lead to improved surface finish and reduced chip formation, but excessive feed may also induce vibrations, causing tool deflection. A balanced approach involves analyzing the material removal rate while maintaining optimal performance levels, often requiring adjustments based on specific machine capabilities and the type of aluminum being machined.

Another crucial factor is the relationship between cutting depth and tool geometry. A shallow cut can minimize deflection, particularly when dealing with softer aluminum grades. However, industry benchmarks suggest that increasing the depth of cut in moderation can lead to faster cycle times without compromising tool stability. Implementing feeds and speeds that align with the cutter’s specific features—like helix angle and flute design—can offer substantial improvements. Additionally, using adaptive control systems allows operators to continuously refine these parameters in real-time, ensuring maximum efficiency throughout the milling process.

How Can Cutting Speeds and Feeds Be Optimized for Stability?

Optimizing cutting speeds and feeds is crucial in CNC aluminum machining to reduce tool deflection and enhance stability during the milling process. For example, cutting speeds ranging from 800 to 1,500 surface feet per minute (SFM) are commonly utilized for aluminum, depending on the specific alloy and tooling employed. Adjusting feed rates significantly impacts chip load and helps maintain a consistent cutting pressure. Excessive chip load can induce vibration, leading to increased deflection and reduced tool life. Therefore, fine-tuning the feed rate to achieve an optimal balance minimizes tool stress while maximizing productivity.

Employing the proper combination of speeds and feeds not only improves machining performance but also contributes to better surface finishes. A well-calibrated relationship between these parameters alleviates adverse conditions like tool chatter, which is often exacerbated by high RPMs and insufficient feed rates. Implementing precise calculations, such as maintaining a chip thickness ratio of 0.001 to 0.0015 inches, can effectively mitigate the risks associated with tool deflection. Analyzing metal removal rates and engaging simulation tools can further provide insights into the optimal settings tailored specifically for the chosen aluminum alloy. These adjustments lead to improved consistency and overall machining integrity.